SEGMENTS AND BUSINESS UNITS

THE INDUSTRIES WE SERVE

Acteon drives down costs for operators by optimising design and installation activities and improving scheduling and resource utilisation. We have the expertise to support the development of large structures in deep water, including floating installations. And provide baseline environmental surveys so that projects can establish appropriate controls for environmental protection.

Acteon has supported the oil and gas industry for decades by delivering cost efficiencies and project timeline savings on large and complex projects in all water depths. Our services include pre-development and front-end-engineering, development drilling services, foundations, moorings, production asset installation, asset integrity monitoring and management, field life extension and decommissioning.

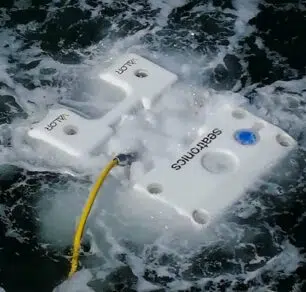

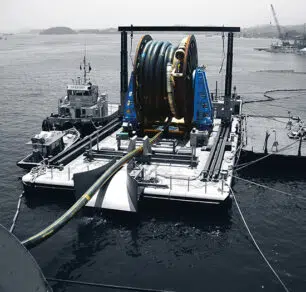

Acteon provides nearshore construction services for marine facilities; these range from geophysical and geotechnical surveys and engineering services to piledriving, foundation work and mooring. Our integrated solutions and domain knowledge help customers to reduce project footprints, increase efficiency, and significantly lower the total cost of infrastructure construction and installation.

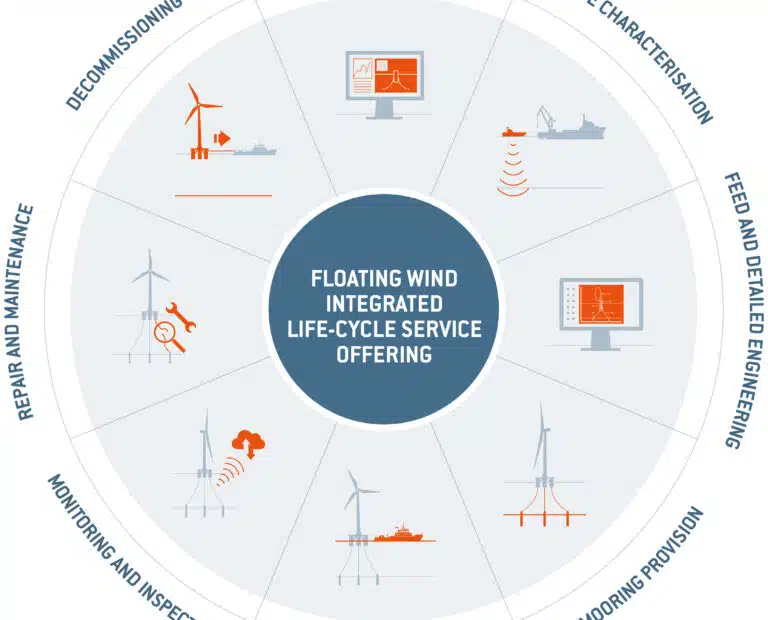

Acteon is at the forefront of the offshore industry’s drive to reduce costs and increase operational efficiency. We define and develop targeted integrated offerings within each industry we serve to allow clients to overcome unresolved challenges associated with asset ownership across all phases of the lifecycle.

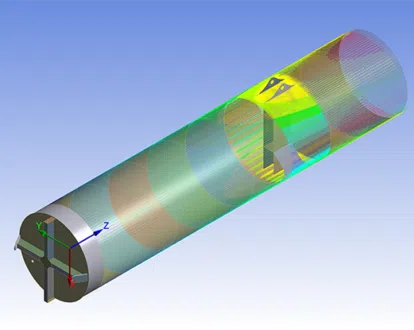

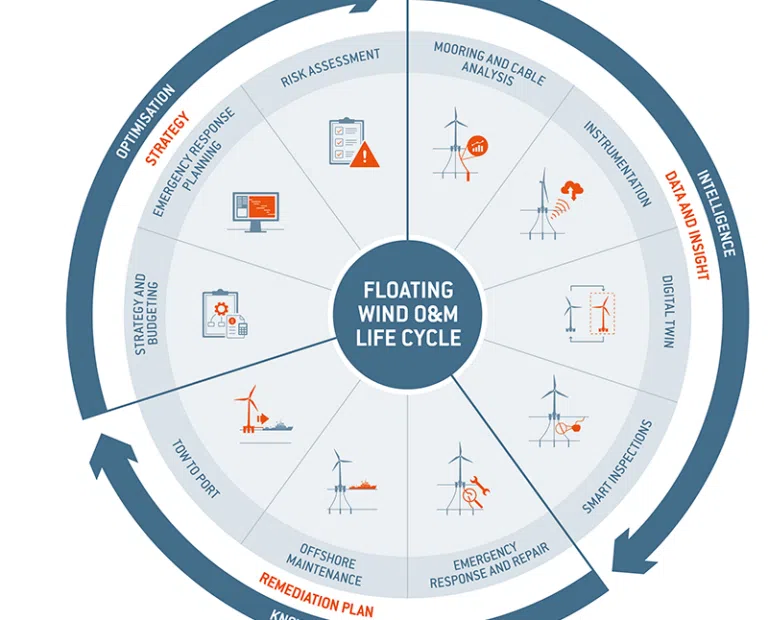

Operations, maintenance and integrity services track record

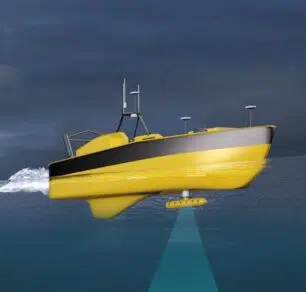

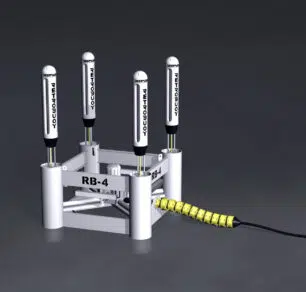

Acteon has a comprehensive range of in-house services and technologies for surveying and inspecting fixed and floating balance-of-plant assets.

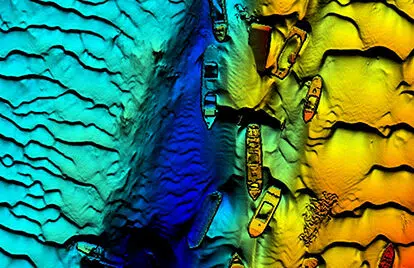

FEATURED WEBINAR: INTEGRATING GEOPHYSICAL AND GEOTECHNICAL SURVEYS FOR OFFSHORE WIND

Learn how combining geophysical and geotechnical surveys can fast-track data insights. Rafal Libera, our Business Development Director for Geo-services in Europe, will share how to achieve seamless surveys within the same year. Stay ahead in the race to the first electron - uncover challenges and proven solutions!

WATCH THE WEBINAR

LATEST FROM ACTEON

-

Acquisition of Acteon Group

Acteon Group, the international marine energy and infrastructure services business, has been acquired by private equity investors Buckthorn Partners and One Equity Partners...

Acteon Group, the international marine energy and infrastructure services business, has been acquired by private equity investors Buckthorn Partners and One Equity Partners... -

Lifecycle support for floating wind: navigating challenges with expertise

As the world transitions toward cleaner energy sources, floating wind projects are emerging as a promising solution. These ventures, however, come with unique...

As the world transitions toward cleaner energy sources, floating wind projects are emerging as a promising solution. These ventures, however, come with unique...